Design & Manufacture Capabilities

Total plant area is 15,000 square meters, including toroidal, EI, and special transformer workshops.

Toroidal Transformer Workshop

Parts of our toroidal transformer production line

Test Centre

Full test facilities are available.

EI Laminated Transformer Workshop

Parts of EI laminated transformer production line

Special Transformer and Line Reactors Workshop

Parts of special transformer and line reactors production line

Noise level and Temperature Rise Test Room

Transformer noise level and temperature rise test room

Salt Spray Tester

The salt spray test (or salt fog test) is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings. Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying metal.

Tunnel Furnace

Infrared tunnel furnace

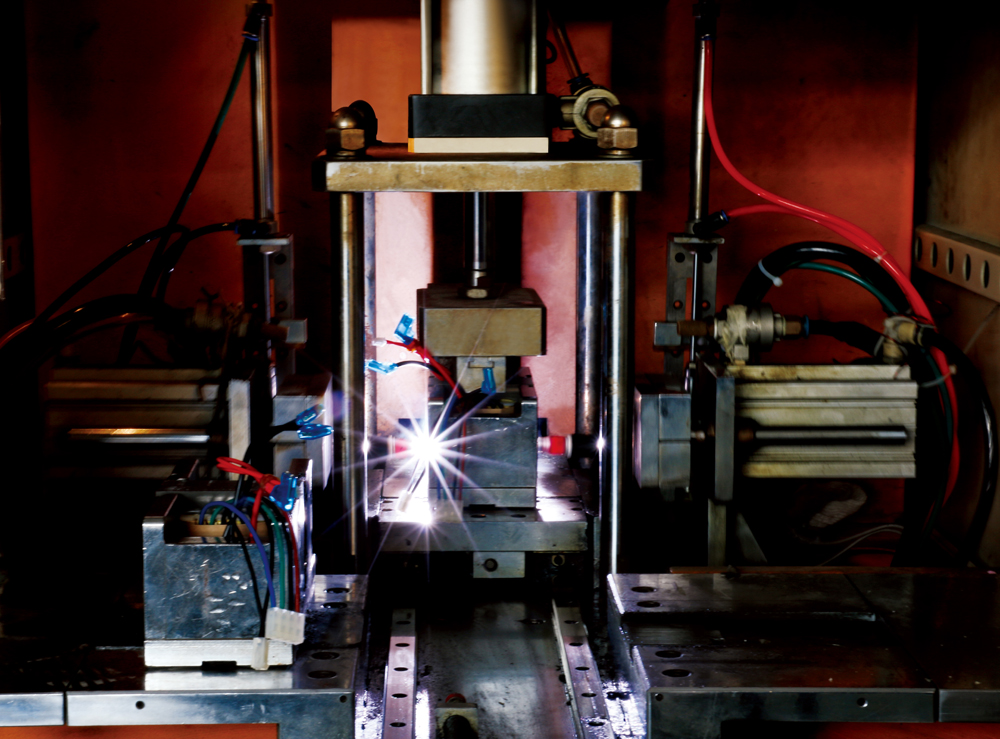

Automatic Arc Welding Machine

EI laminated transformer production equipment

RoHS Tester

Test materials for hazardous substances to ensure that our products meet RoHS requirements.

Humidity Chamber

Equipment for testing the performance of materials in various environments and testing various materials for heat resistance, cold resistance, dry resistance, and humidity resistance

Some Of Other Test Equipment

Transformer routine test equipment.

Special Transformer and Line Reactors Test Lab

Special Transformer and Line Reactors Test Station

Transformer Foil Winding Machine

EI Laminated Core Cutting Equipment